- Home

- About Us

- Programs

- FRA-Fee Structure

- Accreditation

- Research

- BNCA Cells

- International Cell

- UNAI

- Universal Design Cell

- Innovation and Incubation Cell

- Archineering Cell

- Environment Cell

- Publication Cell

- IQAC (Internal Quality Assurance Cell)

- BNCA Consultancy Cell ( BCC )

- CEL (Center For Ecological Landscapes)

- Universal Human Values

- SES RE CELL

- Structure Cell

- Center For Cultural Studies

- Teaching+Learning Laboratory

- Career Counselling & Guidance Cell

- Center for Interdisciplinary Studies in Art and Architecture.

- Students

- Infrastructure

- Library

- IT Infrastructure and Computer Labs

- Digital Fabrication Lab

- Wood Working Lab

- Lab for Environmental and Simulation [LEDS]

- Landscape Research Lab

- Material Museum

- Construction Lab

- Survey And Leveling Lab

- Language Lab

- Studios

- Photography Lab

- Clay Studio

- Immerssive Design Lab

- Acoustic Lab

- Board Room

- Auditorium

- Lighting Lab

- Research

- Contact Us

Digital Fabrication Lab

About

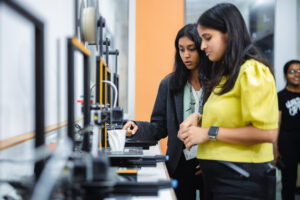

Digital Fabrication Laboratory (DFL) at BNCA stands as a pinnacle of creative space and technological advancement. Since its inception in 2010, the BNCA-DFL has evolved into a fully equipped facility boasting a diverse range of precision prototyping equipment specialized for working with wood, plastics, and metals. This includes cutting-edge tools such as laser cutters and 3D printers, along with the recent addition of a KUKA Kr 30-3 equipped with a milling spindle, enabling the execution of intricate milling tasks that push the boundaries of traditional manual techniques.

At BNCA-DFL, we harness our core competencies alongside a wide array of digital machinery to foster collaborative work on complex projects, empowering individuals to realize a multitude of creative outcomes. DFL serves as a dynamic ecosystem, continually evolving to meet the demands of innovative design and manufacturing processes. It has consistently remained at the forefront of academic institutions in India, pioneering the integration of machine automation for both subtractive and additive manufacturing, with a particular focus on architectural prototyping.

Currently, the DFL houses an extensive range of equipment catering to various material scales, including laser cutting and engraving machines, CNC routers and milling machines, 3D printers, and Dremel toolkits. These resources are organized into three distinct work cells, each tailored to specific fabrication needs. The laser work cell features two cutting-edge laser machines, while the 3D printing work cell is equipped with two advanced 3D printers. Additionally, the robotic fabrication work cell incorporates a CNC router, milling machine, and a state-of-the-art 6-axis Kuka robot. This seamless integration of digital tools with electronic kits (ARDUINO based) and traditional analog hand tools provides comprehensive support for fabrication and innovation.

The BNCA-DFL serves as a hub for creativity and exploration, encouraging interdisciplinary collaboration and pushing the boundaries of design possibilities. It embodies a culture of experimentation and continuous learning, where students and faculty alike can explore new ideas and methodologies in a hands-on environment. The laboratory’s commitment to staying at the forefront of technological advancements ensures that it remains a driving force in shaping the future of design and fabrication in India and beyond.

BNCA-DFL is not just a physical space but a symbol of innovation and excellence, driving forward the intersection of art, design, and technology. Its comprehensive resources and collaborative environment make it a cornerstone of creativity within the academic community, inspiring generations of designers and makers to push the boundaries of what is possible.

| Name | Machine | Machine bed size | Compatible Materials | File Formats | Standard Operation Procedures (SOP) _ DFL Machine |

| Laser cutting machine

|

|

1300 mm X 2500 mm | Acrylic, Softwood, MDF, Softwood, Leather, Rubber, Cardboard, Paper, ABS Sheet

|

PLT, CDR, DWG, DXF, DST, BMP, JPEG, TIFF, GIF, PCX, ect |

Click

|

| Laser cutting machine |  |

460mm x 740mm | Acrylic, Softwood, MDF, Softwood, Leather, Rubber, Cardboard, Paper, Stone, ABS Sheet

|

PLT, CDR, DWG, DXF, DST, BMP, JPEG, TIFF, GIF, PCX, ect. |

Click |

| Creality 3D Printer

|

|

500mm X 500mm X 500mm

300mmX 300mm X 300mm

200mm X 200mm X 200mm

|

STL, obj |

Click |

|

| KUKA ROBOT KR 30 |  |

Max. reach 2033 mm

|

KRL file |

Click Here |

|

| CNC Router and Milling Machine |  |

1200mm x 2400 mm | Softwood, MDF, Cardboard, Foam, PVC, Saag, Plywood, Veneer, Soft Wood, ACP, Cardboard, Marble, Aluminium,

Brass, Copper, Fiber, Hard Plastic, Cement Sheet etc.

|

PLT, CDR, DWG, DXF, ect.

|

Click |

Booking

Students of BNCA can scan to Book the Digital Fabrication lab or Write a mail to yogesh.kulkarni@bnca.ac.in

Protocol of Digital Fabrication Lab

- Safety first: Safety is a top priority in Digital Fabrication Lab. All users should be familiar with safety guidelines, equipment, and procedures before using any tools or equipment. Lab managers should ensure that safety gear such as gloves, goggles, and aprons are available and properly used.

- Respect the equipment: Users should treat all equipment and tools with respect, following instructions and handling them carefully. Equipment should be regularly maintained and checked for safety hazards.

- Share resources: Makers labs often have a limited amount of resources, so users should be encouraged to share tools and equipment. Rules may be established for reserving equipment and managing time limits to ensure fairness and equal access.

- Collaboration and communication: Makers labs are often collaborative spaces, and users should be encouraged to work together and share knowledge. Communication should be clear and respectful, with an emphasis on problem-solving and mutual support.

- Documentation: Projects and experiments conducted in the makers lab should be well-documented, including materials used, procedures, and outcomes. This information can be used for future reference, troubleshooting, and sharing with others.

- Cleanliness: Users should keep the makers lab clean and tidy, returning tools and equipment to their proper place after use. Cleaning supplies should be available, and regular cleaning and maintenance should be performed to keep the lab in good condition.

- Ongoing learning and training: Users should have access to ongoing training and education opportunities to learn new skills and stay up-to-date with advancements in the field.

Overall, the protocol of Digital Fabrication Lab is to prioritize safety, collaboration, communication, and respect for resources and equipment.

______________________________________________________________________________________________________________________________________________________________________________

Safety guidelines for Digital Fabrication Lab

Personal Protective Equipment (PPE): All personnel’s in the lab should wear appropriate PPE such as safety goggles, gloves, and lab coats. The specific PPE needed will depend on the type of work being done in the lab.

- Chemical safety: If your lab involves the use of chemicals, make sure to properly label and store them in a designated area. Ensure that workers are properly trained in the handling and disposal of chemicals, and provide access to safety data sheets (SDS) for each chemical.

- Equipment safety: All lab equipment should be properly maintained, and any faulty or broken equipment should be immediately removed from use. Workers should also be trained in the proper use and handling of all equipment.

- Electrical safety: Ensure that all electrical equipment is properly grounded and that workers are trained in safe electrical practices, such as avoiding the use of damaged cords or plugs.

- Fire safety: Have a fire safety plan in place, including proper storage of flammable materials and fire extinguishers located in easily accessible areas.

- Emergency response: Make sure that workers are trained in emergency response procedures, such as the proper use of eyewash stations and emergency showers.

- Ventilation: Ensure that the lab is properly ventilated, particularly if working with chemicals or other hazardous materials.

______________________________________________________________________________________________________________________________________________________________________________

Roles and Responsibilities students and operators in DFL

A Digital Fabrication Lab is a Prototyping laboratory where individuals can utilize tools and modern machines and technology to create and design a wide range of physical objects. The roles and responsibilities of students and operators in DFL are as follows:

- Students:

- Be respectful of other users and the equipment in the lab.

- Attend orientation sessions and complete any required training before using the lab.

- Follow the lab’s safety rules and procedures to prevent injury to themselves and others.

- Use the equipment responsibly and correctly, and report any malfunctions or issues to the lab operator.

- Keep the lab clean and organized after use.

- Work collaboratively and share ideas and knowledge with other users in the lab.

- Operators:

- Provide training and guidance to new users of the lab.

- Ensure that all equipment is in good working condition and regularly maintained.

- Develop and enforce safety procedures for the lab.

- Keep track of inventory and ensure that supplies and materials are stocked and replenished as needed.

- Manage the lab’s scheduling system and ensure that all users have access to the equipment they need.

- Foster a collaborative and inclusive environment in the lab, and encourage users to share ideas and knowledge with each other.

Revision History: Any changes to this SOP must be documented in the revision history log.

Downlaod Brochure– DFL Booklet 2024